#sponsored post

Injection molding is a manufacturing process used in the production of different parts by injecting liquid material into a mold. In most cases, it is performed with thermoplastic polymers, but it can also be used with other materials like glass and metal. Injection molding has been around for a while, and with technology, it keeps getting better.

So, how does injection molding work?

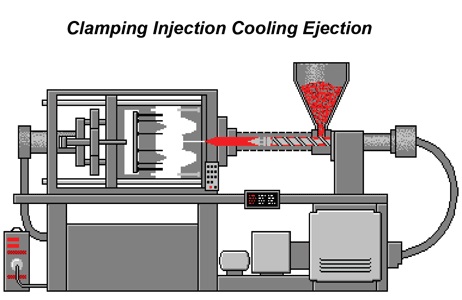

Injection molding is not as complicated as it may sound. It works by heating small pellets of a particular material until they become a molten liquid. The hot fluid is then forced through a nozzle and makes its way into a mold whose internal cavity resembles the part being created. Once in the frame, the molten components are cooled and then removed using injector pins.

Why use injection molding?

Plastic injection molding automates production and plays a significant role in its respective companies. It provides solutions to many designs that would otherwise not be achievable. Some of the advantages of the process include;

The process can be fully automated

One of the most significant benefits to injection molding is that it can be fully automatic. This allows high rates of production since it’s possible to produce numerous parts very effectively. China injection molding companies are taking advantage of the ability to automate the process by doubling up production and meeting the demands of the market.

You can use a variety of materials

Injection molding is not restricted to a particular substance. It can be used across a wide range and also allows a combination of different materials to come up with desirable properties in the final product. This type of injection molding that involves a combination of more than one element is referred to as co-injection molding.

Allows production of highly detailed and intricately designed parts

If you want to create any sophisticated item, then injection molding is the solution you need. Make use of an engineering design firm or a credible in-house department to come up with fantastic designs. However, once you have your part ready and produced through the molding process, there is little finishing work left. Usually, parts emerge looking finished and don’t need extra work to change their design.

It’s possible to make use of mold inserts to make new parts

The good thing with injection molding is that you can change the internal cavity without necessarily redesigning and re-machining the tooling via CNC. Also, with the advancements of technology like Polyjet from Stratasys, you can print your mold tooling using a 3D printer. However, this will only be possible for small scale production.

Considerations Involved in Injection Molding

When it comes to injection molding the small details play a significant role. The parts have to be generated from extremely detailed molds. Usually, the mold design should be created with the help of engineering design experts as well as the experts of the manufacturer. After the design is finished, comes the actual process of working to come up with an end product of acceptable quality. For a company to create highly detailed products that are polished to perfection, then it’s always a good idea to ally with the proper manufacturer.

What is the Cost of Injection Molding?

The price of injection molding varies and depends mostly on the different portions of the entire process. Many variables determine the final cost of a particular part. For instance, the technique used in the molding process plays a crucial role. Also, inputs like prototypes, drawings, and sample parts, among others, contribute to determining the amount of money used in the molding process.

In essence, everything from tolerance tightness to the core metal, additional cavities, core machining, mold size, and the complexity of the parts have an impact on the cost of injection molding. This process is not beyond anyone’s price range. You just have to determine what you are looking for and work towards achieving that.

Injection molding technology is a remarkable piece of invention technology for facilitating finished mass production. It has proved resourceful in coming up with designs that most other forms of productions would never accomplish. With injection molding, companies can design numerous parts and guarantee output on a large scale conveniently. What’s even better the process is also useful in finalized prototypes that play a significant role in consumer and product testing. Injection molding is not only practical but also facilitates flexibility in production.